ISBM MACHINE FEATURES

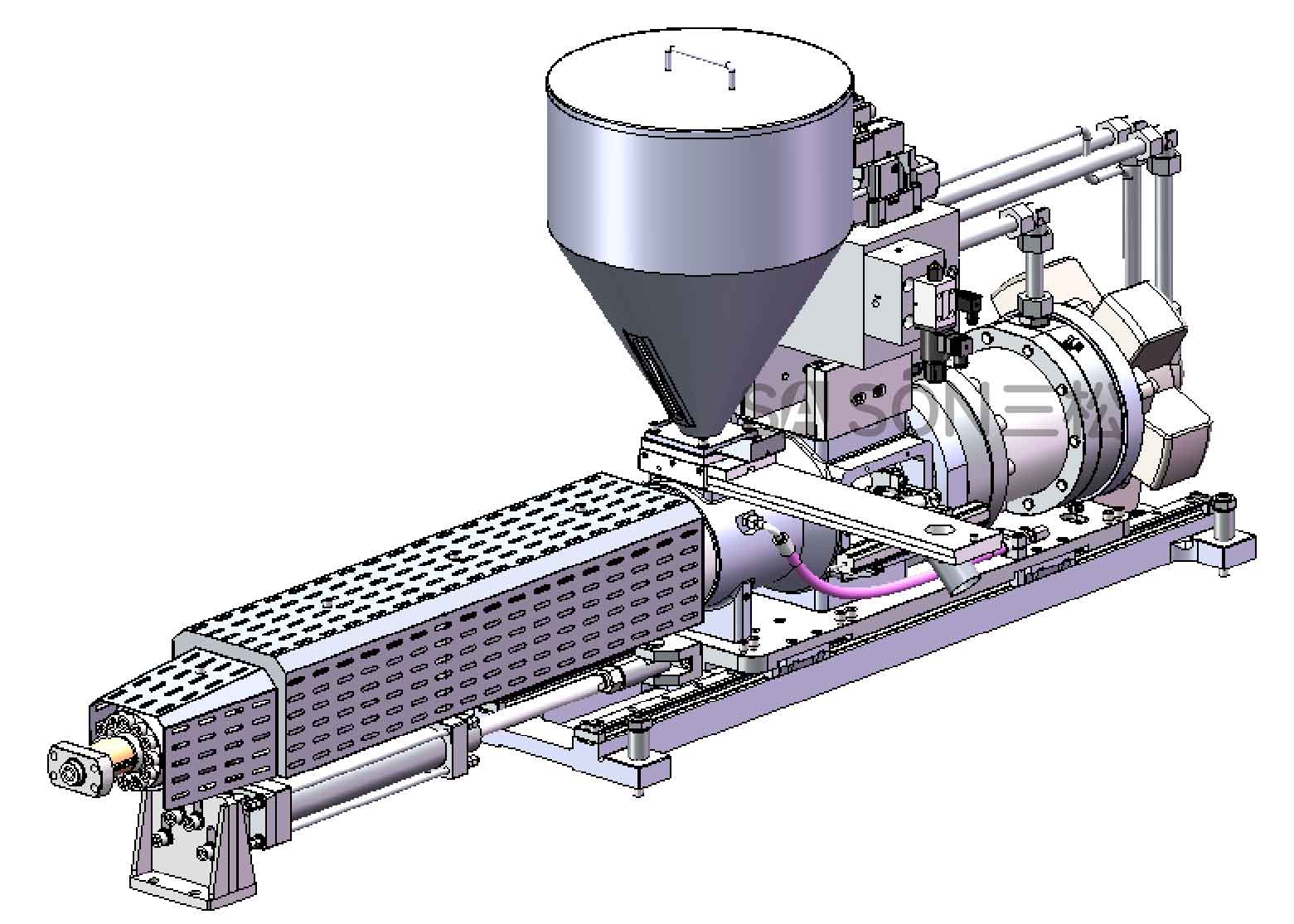

Injection System

The single-cylinder injection system is adopted, which makes the operation more stable and avoids the problem of poor coordination of multiple injection cylinders, it is easy to maintain and has a shorter downtime. The compact structure occupies less space, which benefits the factory layout, and is particularly suitable for factories with limited space.

The 1000cc/rev hydraulic melting motor can melt a large amount of plastic in a short time, providing efficient melting performance, especially suitable for the production of large products or high-volume production needs. It can provide high torque, suitable for high-viscosity and high-filling plastic materials, ensuring a smooth melt process. The hydraulic motor also provides a smooth power output to ensure the stability and consistency of the melt process.

Equipped with a proportional electro-hydraulic pressure control valve, the back pressure can be precisely adjusted through the touch screen (HMI) to optimize the quality of the plastic melt.

Dual linear guides provide precise motion control, reduce friction, and make motion smoother, thereby improving the stability of the injection molding system.

The barrel temperature is controlled by P.I.D. to accurately adjust the temperature to avoid overheating or overcooling, thereby improving the quality of the plastic melt and the consistency of the product.

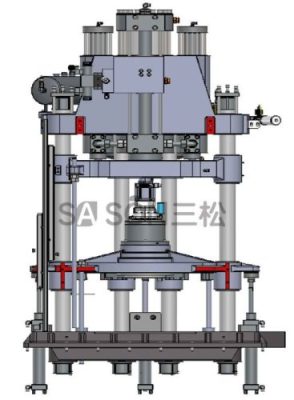

Injection Clamping System

The virtual hydraulic cylinder clamping structure is adopted, and the servo system is combined to achieve fast response control, which improves the clamping efficiency and saves energy. Compared with other domestic injection stretch blow machines, the cycle time is shortened by at least 30% when the same mold is used in production on Sansong’s ISBM machine.

Four large-diameter tiebars enhance rigidity and strength, reduce clamping deformation, and extend service life.

The multi-station rotary mechanism uses a direct connection between the motor and the reducer, abandoning the traditional gear transmission to achieve precise and efficient motion control and position feedback.

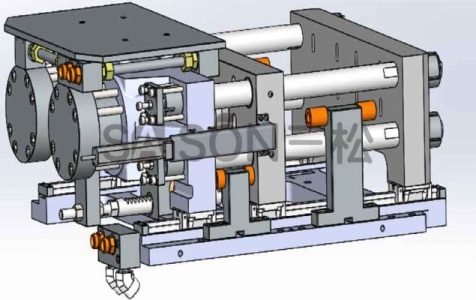

Blowing Clamping System

The hydraulic cylinders are differentially connected to achieve stable and fast mold clamping.

The double hydraulic cylinder clamping structure provides a clamping hydraulic pressure of up to 17kPa.

Large mold space allows for molds with different cavities to be matched to meet various production requirements.

Energy-Saving Servo System

Three energy-saving servo systems: The combination of Delta servo motor and original German ECKERLE high-speed gear pump can significantly save energy.

High-efficiency power source: The original German ECKERLE high-speed gear pump provides excellent volumetric efficiency and strong power.

Advanced control technology: Delta electro-hydraulic servo controller ensures high-speed and high-precision motion control with excellent anti-interference ability.

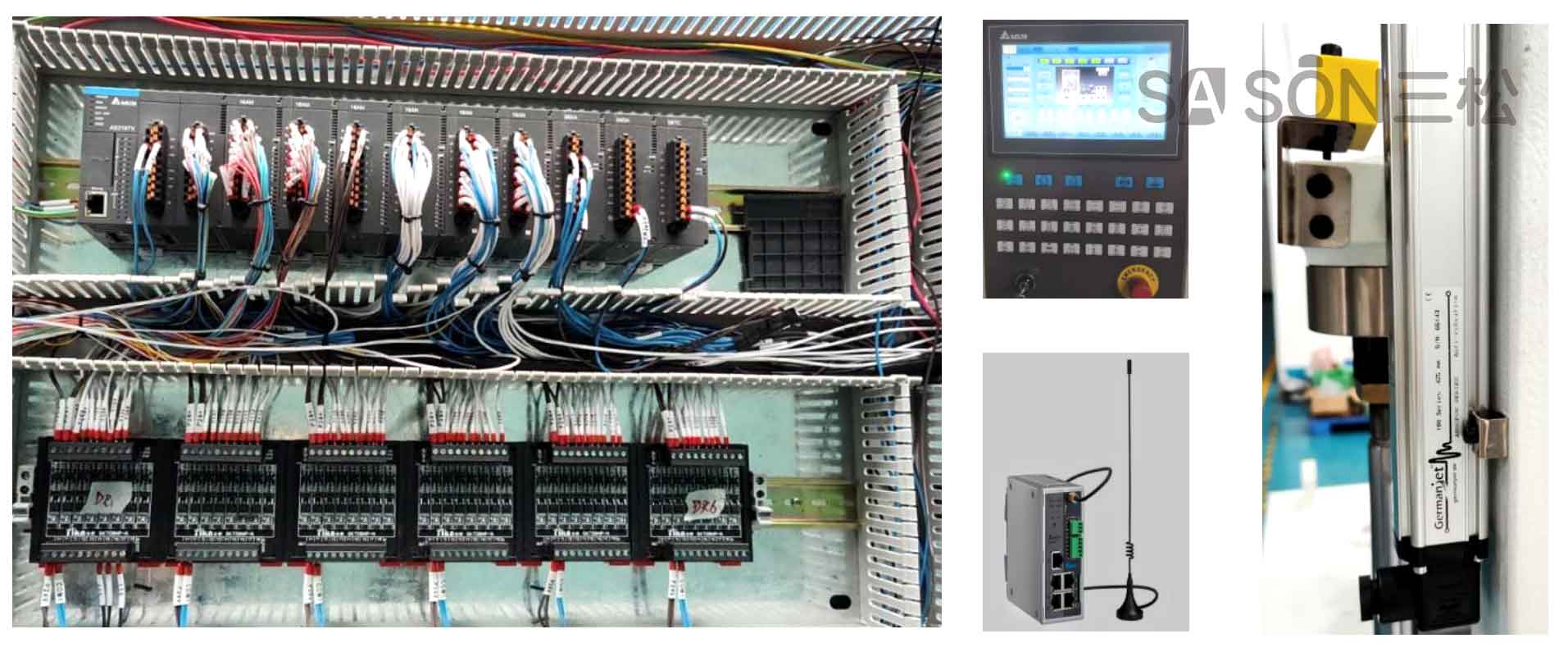

Electronic Control System

Delta PLC achieves digital precision control, improving operating speed and stability.

Delta’s 10-inch human-machine interface (HMI) provides visual parameter adjustment and supports Chinese/English language switching.

Delta PLC’s remote program maintenance device is optional, so customers don’t need to worry about program problems.

Non-contact magnetic displacement sensors provide precise, direct displacement control. The cursor without electrical contact eliminates wear and extends service life.